KRE's WARP 6 Aluminum Pontiac

Cylinder Head

| The NEW fully canted valve aluminum Warp-6 Pontiac Head is NOW available! |

It's finally here. After years of research and development we are excited to introduce to you, the finest cast water jacketed Pontiac cylinder head available. The Warp 6 Pontiac cylinder head! This is KRE's third aluminum Pontiac cylinder head that they have brought to the marketplace. This will be the highest horsepower producing cylinder head in the Pontiac hobby. KRE has spared no expense to make this the ultimate Pontiac cylinder head.

|

|

|

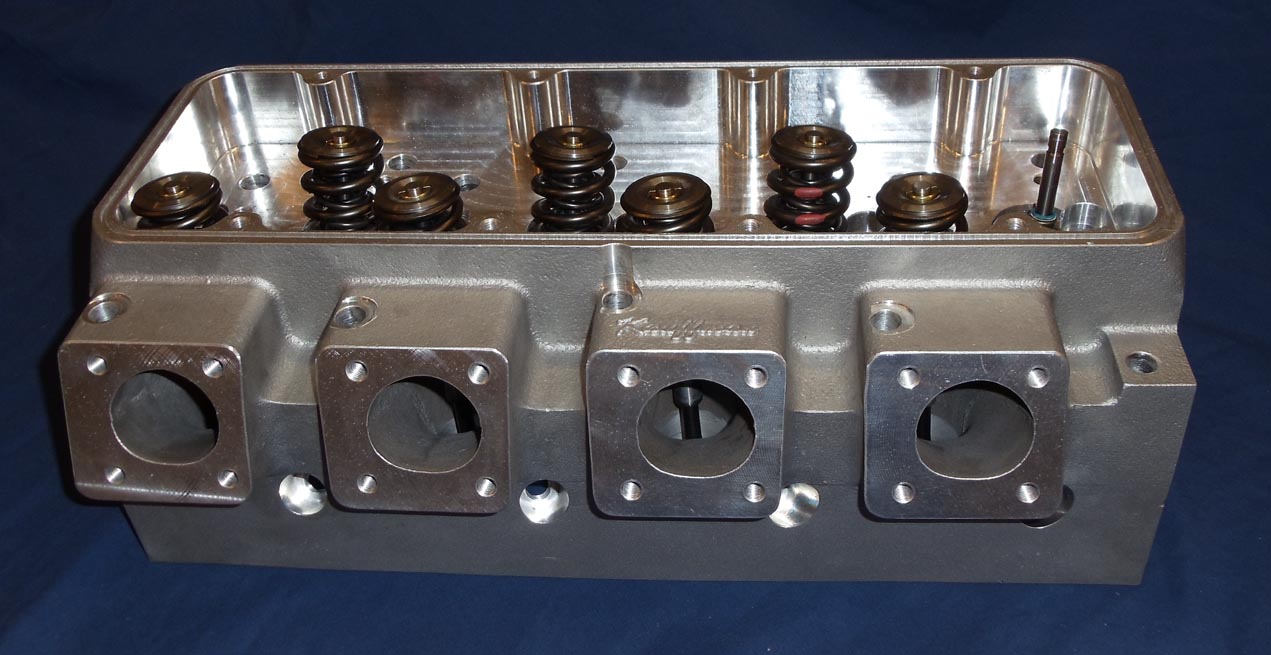

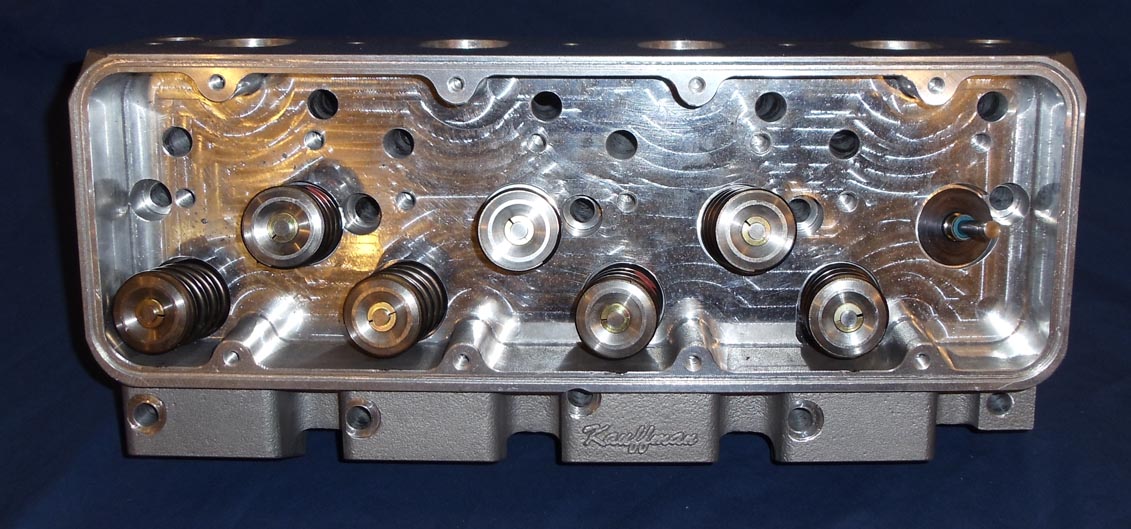

The Warp 6 Pontiac cylinder head is not your common Pontiac cylinder head. From the pictures you can see the valve arrangement is quite different. Your standard Pontiac cylinder head has an arrangement of the following E I I E E I I E. This head would be considered in the motor sports industry as a symmetrical valve arrangement. This means your valve arrangement is laid out as follows E I E I E I E I.

This design eliminates quite a few things that we have fought with on the standard Pontiac design for years. First with this design you see that each and every port is identical in it's shape both on the intake and exhaust. All the ports enter and exit the same way into and out of each chamber as you can see in the pictures. So with the standard Pontiac design you have slight differences in that old design. You have 2 different intake ports (one going one direction and the other going the other direction as they enter the combustion chamber) and even worse on the exhaust side as you have 4 different ports. These all exit the chamber with a slight difference in direction and angle to the port. Plus all of the exhaust ports are exiting with a slight amount of difference into the headers.

As you can see there are many differences and benefits just from the port layout. Now another problem that has plagued the Pontiac engine. This is something we really didn't start fighting until about 10 years ago. Burning the head gasket between the center two cylinders. A couple of things over the years have contributed to this issue. First has been just plain making more power. Power is heat and heat is what we're fighting. The second issue is aftermarket blocks. With the advent of the aftermarket blocks like the K&M Performance MR-1 we have been able to increase the bore size which is turn has given us less material between the cylinders and less head gasket material. More power + less material = less gasket life, plain and simple.

The reason for this problem is the two exhaust valves set side by side in the center two cylinders. The only thing to help remove this heat on a std. Pontiac head created by the valves is the water jacket on both sides of the gasket (ea. block and head jacket). In most cases with higher horsepower engines we just can't move enough water through this area to cool it enough to keep the gasket intact.

|

|

As you can see on the Warp 6 head there are no exhaust valves side by side. With this head you have equal heat distribution in the chambers and across the head gaskets. You can also see from the pictures that the amount of material between the cylinders is enhanced, again leading to more heat dissipation and far longer gasket life.

As you can see many other benefits on this head are quite obvious like the taller intake ports, taller and totally different exit ports, high quench area, spark plug location and of course the canted valves.

Warp-6 Specs

- Canted valve arrnagement 10° x 4° on the intake - 6° x 4° exhaust

- Standard CNC chamber machined @ 60cc's on standard valve size

- Utilizes standard center lifters

- Standard valve size 2.250 x 1.750

- Initial flow of approximately 460 cfm on the intake side

- Can accommodate a 2.40 intake valve and a 1.85 exhaust valve

- Standard seat are a non-Beryllium copper designed for titanium valves

- 1 piece rocker shaft is standard

- Minimum bore size of 4.250

- Machined valve cover O-ring groove and O-ring (no valve cover gasket needed)

- Out of the box heads make 1104 HP and 823 Tq on a 535 CID engine

Performance Updates:

Dyno info:

| Bare Castings | Complete Heads ¹ | Port Work |

| 60cc | 60cc | 500 cfm |

¹ Complete heads come with Ferrea Titanium valves, titanium retainers, 10 degree locks, PC seals, Manley Nex-tek roller cam springs for max .900 lift, spring locators and 5 angle valve job.

|

|

|

Warp 6 Accessories

|

|

For superior strength, accuracy and rigidity we designed a 1 piece billet aluminum rocker stand. With the help of T&D rocker arms we've designed the best setup for high rpm horsepower. We've spent years of product testing for the development of this shaft systems for the Warp-6 Pontiac cylinder head.

KRE/T&D Rocker shafts for Warp-6 heads -|

|

The valve covers are light weight welded up sheet metals.

Warp-6 Valve covers -

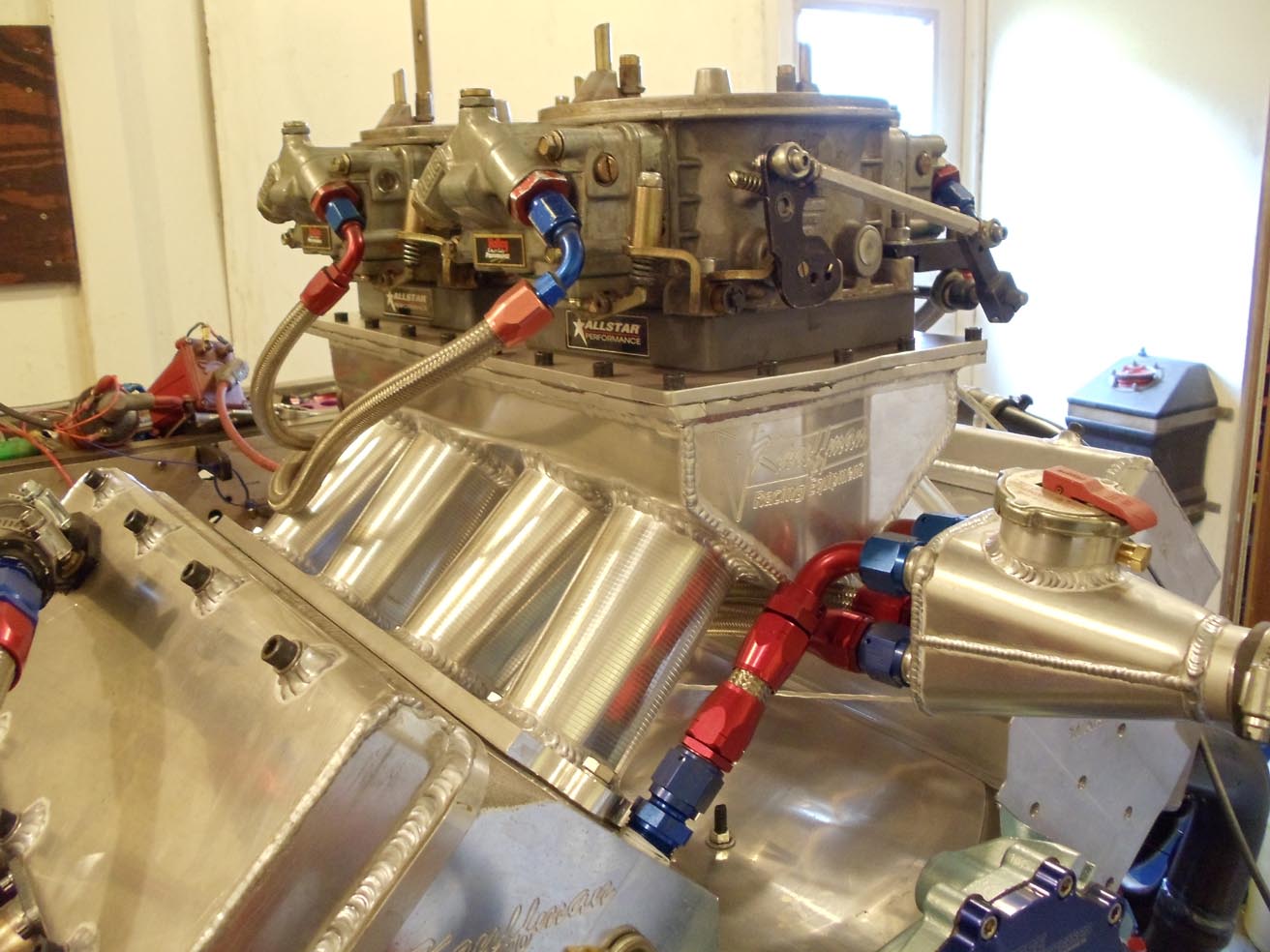

Designed for the Warp-6 heads. This sheet intake has runners made from solid billet material. CNC'd to exact spec's for each and every combo that we will build

Warp-6 Sheet Metal Intake - Warp-6 Ross Custom Pistons -The water manifold is a welded up piece to transfer water from all 4 corners of the engine. The piece serves the same purpass as a std. water cross over on a regular Pontiac intake manifold. Comes with 4 - 10 AN fittings and std. 1 1/4 hose end.

Warp-6 Water Manifold -These steel header flanges come in std. 2 1/8" tube size. Laser cut to size out of 3/8" material.

Warp-6 Header flanges -